Common Implementations of Chemical Defoamer Across Various Sectors

Wiki Article

Checking Out the Benefits of a Chemical Defoamer in Production and Manufacturing

The assimilation of chemical defoamers in production and production processes supplies a calculated benefit by dealing with one of the consistent difficulties in commercial operations: foam control. As producers strive to optimize processes and enhance consumer contentment, the duty of chemical defoamers comes to be significantly essential.Relevance of Foam Control

While the existence of foam in producing procedures can occasionally seem safe, effective foam control is critical for enhancing functional performance and product top quality. Foam can disrupt different stages of manufacturing, leading to inefficiencies that might raise prices and expand processing times. In markets such as food and drink, drugs, and chemicals, uncontrolled foam can obstruct devices, interrupt automated systems, and ultimately cause item inconsistencies.

Carrying out reliable foam control approaches not only improves productivity but additionally supports regulatory compliance in sectors where foam can bring about environmental worries. By using chemical defoamers, suppliers can reduce these difficulties, ensuring smoother operations and higher-quality output. Inevitably, prioritizing foam control is an essential element of production that can produce substantial advantages in terms of security, item, and efficiency reliability.

Sorts Of Chemical Defoamers

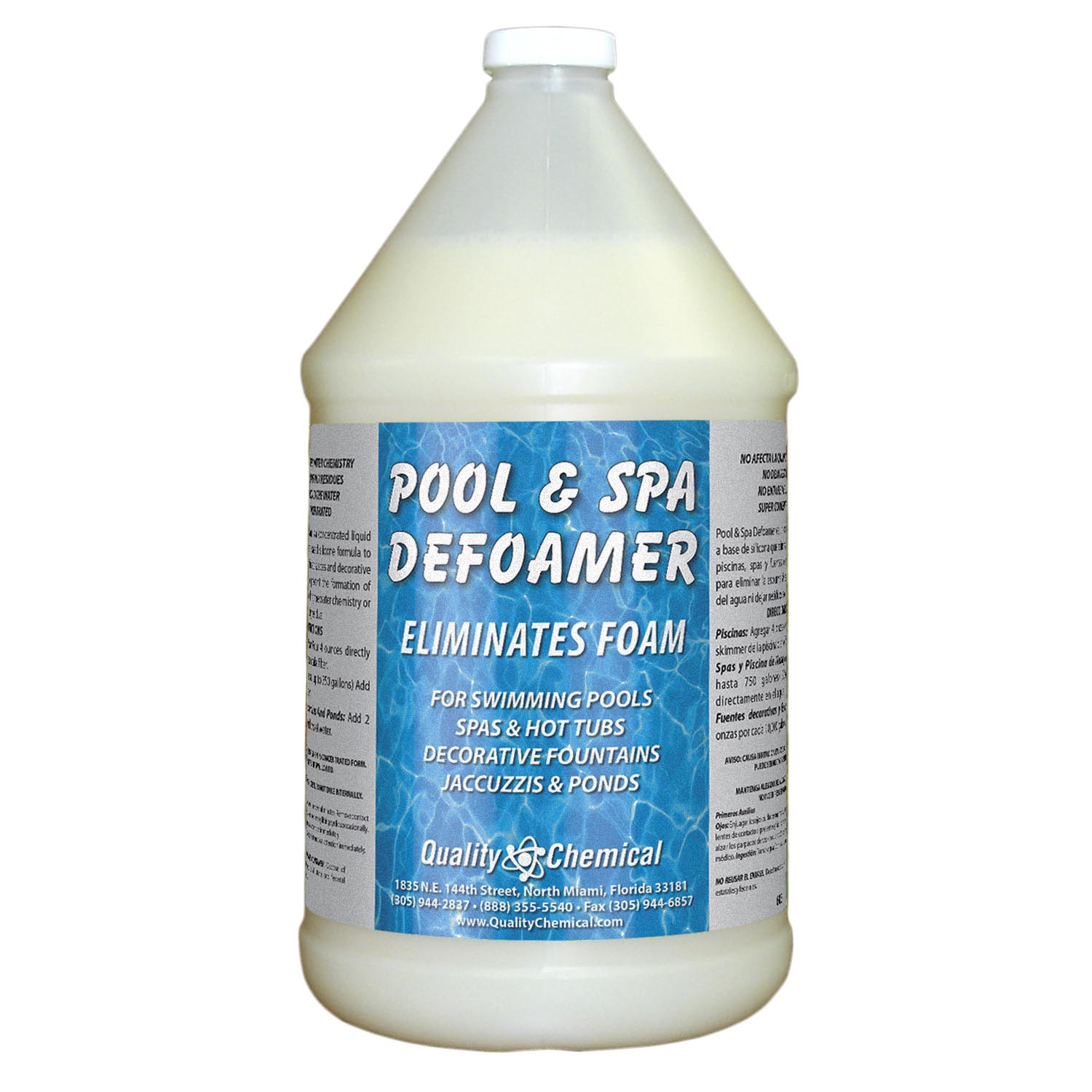

What kinds of chemical defoamers are offered for manufacturing procedures, and how do they vary in application? Chemical defoamers can be categorized into three major kinds: silicone-based, natural, and inorganic defoamers. - Chemical Defoamer

Organic defoamers, usually originated from natural oils or fatty acids, are effective in a series of applications, consisting of food and drink production. They are frequently favored for their reduced poisoning and ecological effect, making certain conformity with market laws.

Each type of defoamer offers distinctive objectives based upon the chemical structure and the particular needs of the production procedure, allowing suppliers to pick the most appropriate alternative for their certain needs.

Advantages in Production Performance

Chemical defoamers play a crucial function in boosting manufacturing efficiency by efficiently controlling foam generation during numerous processes. Foam can impede manufacturing prices, disrupt tools operation, and result in costly downtime. By including chemical defoamers, manufacturers can mitigate these issues, ensuring smoother workflow and enhanced overall performance.Making use of chemical defoamers helps enhance the functional efficiency of equipment such as pumps, mixers, and activators. With decreased foam, these machines can operate at their meant capacity, decreasing the danger of overflow and enabling constant handling. This causes far better source use and greater throughput.

Moreover, chemical defoamers help with faster handling times by lowering the moment needed for foam elimination. This acceleration can dramatically influence production timetables, allowing makers to fulfill consumer demand more efficiently. In addition, using defoamers adds to reduce energy consumption, internet as equipment runs a lot more efficiently with decreased foam interference.

Influence On Product High Quality

Foam control is not just important for maintaining performance in making procedures yet additionally plays a significant duty in making sure item quality. Excessive foam can introduce air right into solutions, leading to variances in the final item. This can materialize as problems such as spaces, unequal structures, or substandard finishes, which undermine the desired high quality and efficiency of the item.In addition, foam can hinder the homogeneity of mixes, leading to irregular distribution of active ingredients. In industries such as coverings, cosmetics, and food manufacturing, this can lead browse around this web-site to variations in shade, taste, and overall efficiency. By utilizing a chemical defoamer, makers can alleviate these risks, making certain that products meet strict top quality specs.

In addition, controlling foam can enhance the security of suspensions and emulsions, which is essential for ensuring shelf-life and customer complete satisfaction. With boosted item consistency and decreased defects, manufacturers can accomplish higher standards of quality assurance, inevitably leading to raised customer trust and brand name commitment.

Cost-Effectiveness and ROI

Effective foam control not only enhances item top quality however additionally contributes substantially to the total cost-effectiveness of manufacturing procedures. The use of chemical defoamers minimizes foam-related problems, which can otherwise result in production delays, equipment malfunctions, and raised energy usage. By lowering foam, suppliers can enhance their procedures, causing higher throughput and efficiency.Purchasing chemical defoamers can generate a substantial roi (ROI) The first expenses connected with these ingredients are commonly offset by the cost savings realized from lowered downtime and enhanced product return. Furthermore, improved item quality can minimize waste and remodel expenses, better reinforcing financial efficiency.

Additionally, effective foam control can cause reduced water and power use, adding to lower operational expenses. This is particularly crucial in sectors where source effectiveness is extremely important. By incorporating chemical defoamers into their procedures, manufacturers can accomplish lasting savings while maintaining affordable prices in the industry.

Final Thought

In verdict, the integration of chemical defoamers in manufacturing and production processes is crucial for enhancing operational effectiveness and enhancing item high quality. Efficient foam control adds to improved tools performance, minimized handling times, and lessened downtime, ultimately resulting in significant cost financial savings. In addition, constant product formulas foster customer complete satisfaction and brand commitment. The benefits offered by chemical defoamers not only support regulative conformity yet also give an affordable edge in the production landscape.The assimilation of chemical defoamers in manufacturing and manufacturing processes supplies a critical advantage by attending to one of the persistent obstacles in industrial procedures: foam control.While the existence of foam in Get More Info producing processes can in some cases appear harmless, efficient foam control is crucial for maximizing functional performance and item top quality.Chemical defoamers play a crucial function in boosting making performance by effectively controlling foam generation throughout different procedures.Additionally, chemical defoamers facilitate faster processing times by reducing the time needed for foam elimination. Furthermore, the use of defoamers contributes to lower power consumption, as equipment operates much more effectively with lowered foam interference.

Report this wiki page